Work Package 3

Designing an energy-efficient milling machine

Latest update (July 2025)

Alec Anderson from Koolmill is currently in India testing the machines. All three machines are working well, if not at full capacity, and the rice broken during processing has been reduced from 25% (Buhler Mill) to 10%. With this positive result, the miller that Koolmill is working with expressed wanting to have another set of machines.

In their UK site in Sheffield, the team have had challenges with the 3D printers at first but have been eventually resolved. All are now up and running again (all bar one) and making progress on the aesthetics.

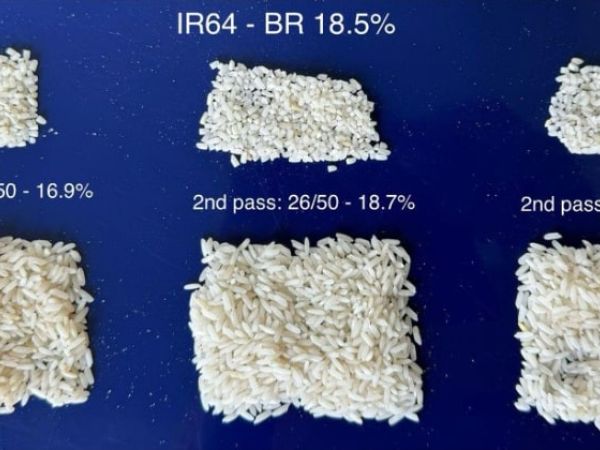

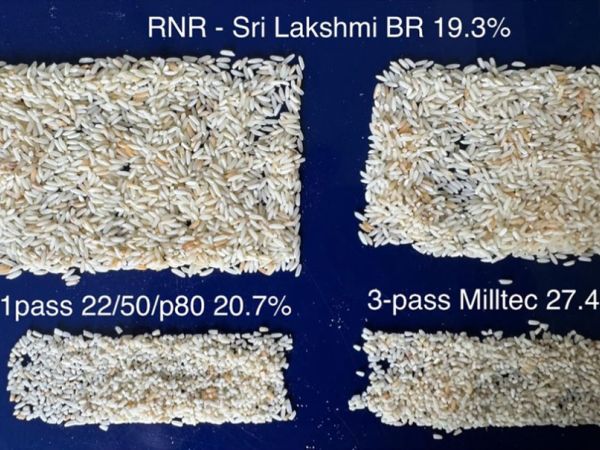

The trials with new chambers have been interesting with a 33% increase in size effectively doubling the capacity. The cost is an increase in net broken rice of <3% (that is the rice broken by Koolmill processing from brown to white in a single pass) as seen in the photo below. However, depending on the specification of the finished product the value of the extra capacity will in some instances outweigh the loss value from the extra broken rice. Koolmill broken rice is still significantly less than conventional mills.

March 2025 update

KoolMill Systems Ltd. is an SME delivering a modern, ultra-low power, simplified, and sustainable approach to cereal milling. In this project, Koolmill is developing an energy-efficient milling machine to enhance farm productivity and strengthen the market value chain.

The fabrication process is progressing smoothly. After several redesigns, the milling drum, which regulates machine performance, is now within specification. Additionally, the frame has been reinforced, and the top plate stiffened, ensuring optimal performance.

Several rice varieties have been mill-tested using the milling machine.

Currently, the team is commissioning its first Machinery as a Service (MaaS) contracted commercial mill in India. This will provide them with invaluable experience and data which will have a direct impact on the success of their introduction of Koolmill to the Philippines in 2025.

Work Packages

Work Package 1 and 2

Establishing climate-friendly practices in rice production and farm operations through innovative technologies

Work Package 4

Analysing socio-economic and environmental perspectives on bioenergy generation

Work Package 6

Fostering a climate-resilient environment through sustainable rice straw management practices