Work Packages 1 and 2

Establishing climate-friendly practices in rice production and farm operations through innovative technologies

Latest update (July 2025)

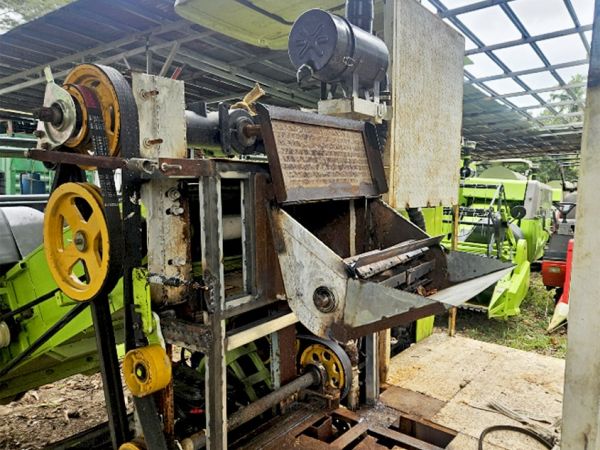

During this period, Straw Innovations Ltd. officially registered their "Straw Traktors" as a trademark, granting them the exclusive right to use it on their agricultural machinery. This signifies that their tractors are now legally recognized as a distinct and protected brand. Alongside this, the team is continuously improving their prototype designs, being able to fully utilize once available for use in commercial scale.

Thus far, there are already 18 units of combine harvester deployed to 15 selected areas in Laguna and Quezon Province for testing, in time for harvesting in the dry season.

Testing of the Straw Traktor (™) at the field sites.

Assembly of additional attachments for Straw Traktor (™)

Meanwhile, Work Package 2 is continuously exploring the six biogas co-digestion setups, each utilizing varying feedstock ratios. These setups use a combination of rice straw and dairy waste. Concurrently, the team is collaborating with a biogas consultant from Work Package 6 to further enhance the experimental designs. Data recording and monitoring are conducted on a daily basis.

Stakeholder Engagement and Institutional Support

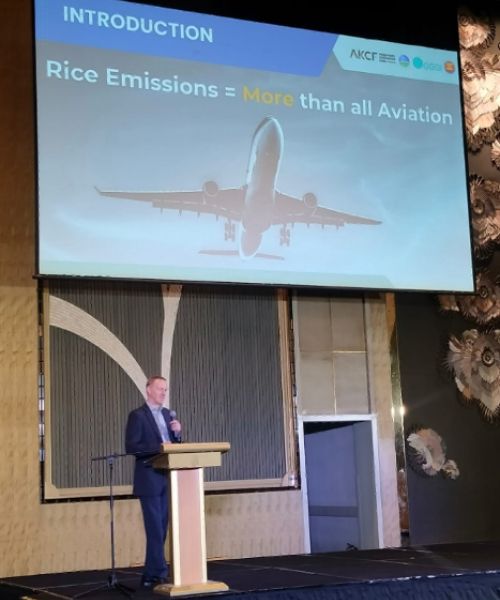

Straw Innovations Ltd. Founder, Craig Jamieson together with Brian James Arevalo, CEO; Jay-Rness Ceria, brand and marketing manager; and Laumar Alan Dave Grafilo represented the company to the In-country Kick-off ceremony and 1st Methane Reduction Committee (MRC) Meeting organized by the ASEAN-Korea Cooperation for Methane Mitigation in May 2025 in Manila, Philippines. The team were able to network and promote with various methane mitigation advocates, including representatives from Global Green Growth Institute (GGGI), Department of Environment and Natural Resources (DENR), and the Association of Southeast Asian Nations (ASEAN).

Mr. Craig Jamieson, along with Mr. Arevalo, Mr. Ceria, and Engr. Grafile, promote sustainable rice straw management as mitigation strategies for reducing methane emissions particularly in the agriculture sector.

Aside from participating at the 1st MRC Meeting, the team also took part at the Asia Clean Energy Forum held at the Asian Development Bank (ADB) headquarters in Manila, Philippines, where they explored potential collaborations with various institutions in finding solutions toward sustainable energy and security.

As the project advances toward promoting climate change mitigation, Jay-Rness Nanes represented the team at the 1st Stakeholder Consultation Workshop titled "Advancing Climate Ambition: Transforming Agri for the PH." During the event, the team advocated for the inclusion of rice straw management as a climate mitigation strategy in the agriculture sector. The discussion highlighted potential policy and measures (PAMs) that could support the implementation of the Philippines’ nationally determined contributions (NDCs, particularly in the agriculture sector.

ADB-initiated consultation workshop for the drafting of PAMs in support of the Philippines' NDC, to be submitted under the Paris Agreement.

In a separate engagement, trainees from the International Rice Research Institute (IRRI) Education visited the rice production facilities of Straw Innovations Ltd. in Pila, Laguna. Led by Engr. Laumar Grafilo, the group had the opportunity to learn about the tractors and operational processes at the site. The Straw Innovations facility remains open to interested individuals who wish to observe the team's ongoing operations firsthand.

Engr. Grafilo shared how Straw Innovations showcases the available tractors at the site and demonstrates their use of rice straw in sustainable operations.

May 2025 update

Scaling Up an Innovative Rice Straw Harvesting System

During this period, the team focused on the improvement of Straw Traktor™ design to further improve its straw collection capacity. Repairs and maintenance of harvesters were also accomplished to ensure their readiness for the upcoming dry season harvesting operations.

Commercial harvesting and expansion of client farm base: An additional of five Zoomlion harvester units were added to the fleet of rice harvesting machinery bringing to a total of 18 harvester units for preparation and deployment in Laguna as well as Quezon area.

Dry season straw collection plan: Created straw collection plan for the upcoming dry season straw harvesting. This includes the deployment of three straw collection methods - use of self-propelled Zoomlion baler, the Straw Traktor™ with improved design to increase collection capacity, and the use of forage harvester as well as simulation of their respective operations to evaluate economic feasibility

Installation, operation, and performance analysis of unit-scale AD system: The experiment was expanded to six 1000L gas collectors using IBC tanks, each setup corresponding to treatments with varying feedstock ratio. The setup was fully installed on 16 December 2024 while data recording on daily gas production is still ongoing.

Optimizing Biogas Utilization in Rice Production

During this period, the team focused on expanding its previous co-digestion setup through installation of six co-digestion AD setup with different feedstock ratios. Site and facilities preparation were also done for straw storage - for use in co-digestion and at the same time as fuel/heat source for rice drying through thermochemical reaction.

Unit-scale co-digestion experiment: Six co-digestion AD was installed and operated for biogas production using rice straw and dairy wastes as feedstock. Monitoring and recording of gas production for all setup was done on a daily basis. Relevant compliance regulations for biogas production were also revisited and reviewed for compliance.

Exploration of other heat sources: Other sources of heat for rice drying were explored - particularly straw. The team is also in talks with its suppliers on the installation of a vertical grain dryer with biomass furnace.

Site & facilities preparation: Clear steps were undertaken to allocate storage area for straw including site clearing and earthmoving operations as well as warehouse improvement for the installation of grain dryer and storage.

Mobile pyrolyzer: The team is looking into possible deployment of Takachar's mobile pyrolyzer - to test the possibility of utilizing the generated waste heat for rice grain drying operations.

March 2025 update

Straw Innovations Ltd leads the Rice Straw Bioenergy Hub and is transforming rice straw into renewable energy for farmers in the Philippines.

To optimize the removal of rice straw from paddy fields, Straw Innovations has adopted a variety of advanced harvesters. This approach could potentially lower the costs of harvesting and collecting rice straw, addressing one of the major challenges in rice straw management. Traditionally, the slash-and-burn method has been a common practice, or rice straw is simply left to decay in the field. Both practices contribute significantly to greenhouse gas emissions, making the need for more sustainable alternatives even more urgent.

Testing of straw reaper in San Pablo Norte, Sta. Cruz, Laguna in the Philippines (May 2024)

Meanwhile, the team is also working on testing out renewable energy technologies that could power rice drying. Thus far, the team already explored gasification, and anaerobic digestion (biogas production), and in 2025, they plan to execute the pyrolysis method.

Conducted several sets of anaerobic digestion treatment, exploring various ratio and proportion that will highlight rice straws potential for biogas production.

By the end of 2025, it is expected that all operations from efficient straw collection, through transportation and processing at the hub, to productive bioenergy use for drying and milling rice, will be completed. The system holds potential for cutting rice emissions by more than 50%, whilst creating added value and jobs for local rice farming communities.

New facility in Pila, Laguna

Work Packages

Work Package 1 and 2

Establishing climate-friendly practices in rice production and farm operations through innovative technologies

Work Package 4

Analysing socio-economic and environmental perspectives on bioenergy generation

Work Package 6

Fostering a climate-resilient environment through sustainable rice straw management practices