Every year, 300–400 million tons of rice straws are burned as waste or left in flooded paddy fields across Asia, emitting greenhouse gases (GHG) and worsening the climate.

Despite the environmental laws prohibiting the improper disposal of rice straws, such as the Solid Waste Management Act of 2000 (Republic Act 9003) and the Clean Air Act of 1999 (Republic Act 8749), a PhilRice report in 2016 shows that 70 percent of rice farmers burn rice straws (Sapnu, 2016).

To resolve this dilemma, Straw Innovations Ltd. has partnered with the Southeast Asian Regional Center for Graduate Study and Research in Agriculture (SEARCA), Koolmill Systems, and Aston University on a groundbreaking collaborative project, "Rice Straw Biogas Hub," to address the issue of rice straw mismanagement. This project aims to significantly reduce GHG by transforming agricultural rice production residue, rice straw, into a clean energy resource such as biogas through cutting-edge technologies. Beyond introducing advanced technological development, the project also emphasizes understanding the farmers' viewpoints and involving them as crucial partners in the global fight against climate change.

Biogas is an odorless, colorless gas mainly consisting of methane and carbon. Its renewability and cost-effectiveness offer a sustainable alternative to liquefied petroleum gas (LPG) and other fossil-based energy sources commonly used for cooking in households.

From waste to wealth

SEARCA, through the Emerging Innovation for Growth Department (EIGD), conducted a "Training on Biogas Production from Agricultural Wastes" on 15–16 February 2024. The two-day event spotlighted the technical know-how of converting and utilizing rice straw and other agricultural wastes as clean energy, replacing fossil fuels.

The lectures took place at SEARCA's Umali Auditorium in Laguna, while the practical, hands-on session focused on biogas production was held at the Pacwood Site's biogas facility, managed by the Environmental Sanitation Center (ESC) in Tunasan, Muntinlupa City,

Nineteen agricultural officers and lead farmers from public and private agricultural institutions in Laguna and Nueva Ecija participated in the training.

Dr. Nur Azura Binti Adam, SEARCA's deputy director for programs, highlighted in her welcoming message the economic uses of "dayami" (rice straw), which provide environmental opportunities to mitigate climate change. Aside from aspiring for an informational engagement from the training, Dr. Nur instilled the idea that "burning dayami is burning money."

Atty. Eric Reynoso, SEARCA's EIGD program head, provided an overview of the Rice Straw Biogas Hub (RSBH) initiative, explaining SEARCA's role of analyzing the greenhouse gas emissions of the rice value chain from preplanting to marketing and creating an enabling environment that will improve rice straw management.

From wasteful to useful

Dr. Victor Luis, Jr., a biogas energy expert, spearheaded the lecture series with a discussion of converting rice straw into renewable energy resources anaerobically or without oxygen. Dr. Luis likened the process to an "assembly line" with two types of workers: acid-forming and methane-forming microbes. Every step and worker must coordinate and balance to achieve an ideal environment for anaerobic digestion.

Dr. Luis engaged with the participants while discussing the vital factors influencing anaerobic digestion.

Dr. Luis engaged with the participants while discussing the vital factors influencing anaerobic digestion.

The interactive discussion gave the delegates an idea of how different anaerobic digesters work. Although any organic material could be a potential substrate, Dr. Luis said that dry leaves, such as rice straws, are one of the raw materials that can produce burnable biogas.

From formidable to affordable

Dr. Ngo Thí Thanh Truc, deputy head of the Faculty of Environment and Resource Economics in the School of Economics at Can Tho University in Vietnam, presented their team's farmer-friendly digester utilizing rice straw and water hyacinth. She highlighted how the high-density polyethylene (HDPE) digester known as 'Subprom' can potentially replace the commercially available digesters made with concrete and plastic.

Affordable biodigester. Dr. Thanh Truc shared her insights about their HDPE digester, Subprom, and how it allows farmers to work independently because of its user-friendly and low-maintenance feature.

Affordable biodigester. Dr. Thanh Truc shared her insights about their HDPE digester, Subprom, and how it allows farmers to work independently because of its user-friendly and low-maintenance feature.

Aside from requiring less maintenance, the fabrication of Subprom has been proven to be more sustainable and cost-effective, amounting to less than USD400 with a lifespan of up to 15 years. Unlike common digesters that need animal manures (from cow or swine), the Subprom digesters can run up to two months with hyacinth and rice straw as sole feedstocks—an impressive innovation, especially for households that own less than three swine or none. Dr. Truc shared that Subprom digesters are now being adopted by Vietnam's Ministry of Agriculture and Development (MARD).

Dr. Luis and Ms. Lichelle Dara Carlos, EIGD program specialist, expressed enthusiasm for the technology and suggested collaborating with Dr. Truc's team to potentially bring Subprom digesters to the Philippines.

From linear to circular

On the second day of the training, the RSBH team and the participants from Nueva Ecija and Laguna learned more about the biogas conversion process through the waste management initiative of the ESC in Tunasan, Muntinlupa City.

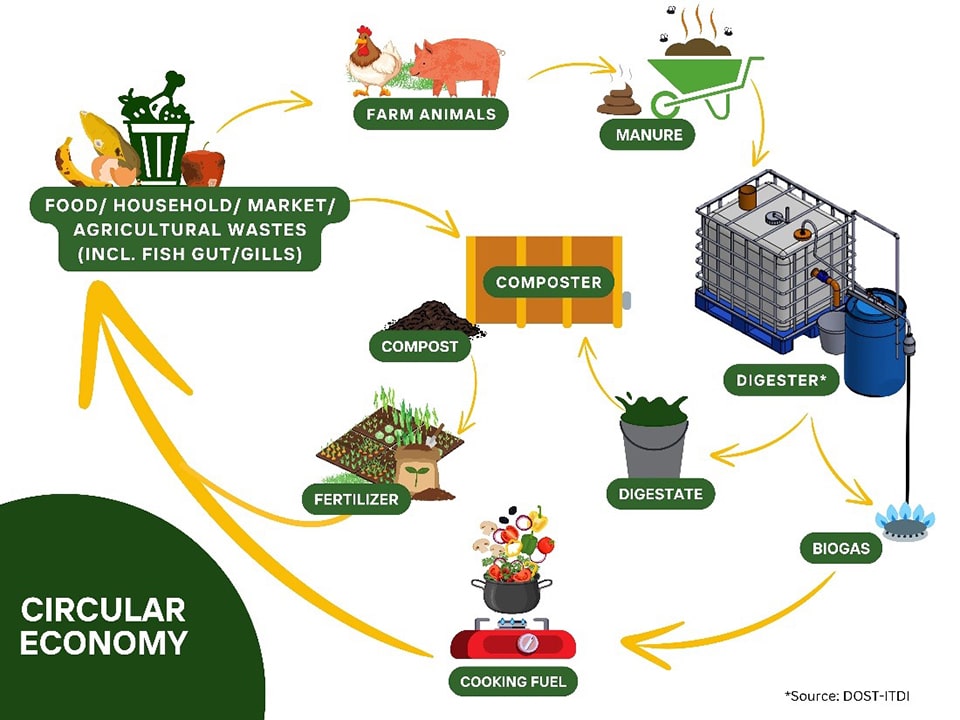

Engr. Vincent Alon, ESC's Solid Waste Management Division head, introduced the city's waste segregation and management initiatives, shifting from a linear to a circular economy.

Sustainability in action. Muntinlupa's ESC is pioneering the circular economy by converting agricultural waste into biogas for cooking and digestate for composting, showcasing a sustainable cycle of waste segregation and biogas production.

Sustainability in action. Muntinlupa's ESC is pioneering the circular economy by converting agricultural waste into biogas for cooking and digestate for composting, showcasing a sustainable cycle of waste segregation and biogas production.

Muntinlupa City's circular economy includes using kitchen, market, and sometimes industrial, agricultural wastes for the consumption of animals and as feedstock to the portable digester. Feedstocks and animal manures are converted to biogas that consumers can use for cooking, while the digestate can be turned into compost or fertilizers used for vegetable or horticultural gardening.

Engr. Alon discussed the ESC's sustainable segregation initiative by adopting the DOST portable digester.

Engr. Alon discussed the ESC's sustainable segregation initiative by adopting the DOST portable digester.

A highlight of the ESC initiatives is the pilot testing of the one-cubic meter biogas digester (see brochure on portable biogas digester) designed by the Department of Science and Technology's Industrial Technology Development Institute (DOST-ITDI) for use by the ESC. The biodigester technology is part of DOST-ITDI's environmental solution to the increasing problem of waste mismanagement, especially concerning animal manure and household waste.

Engr. David Herrera, senior engineer under the Environmental and Biotechnology Division of the DOST-ITDI, presented the design and capacity of the DOST-fabricated digester and its ability to convert manures and agricultural wastes, such as those collected from public markets and households, into biogas — a renewable energy source. The digester can process 210 kg of the substrate into methane, fueling half an hour of cooking.

Engr. Herrera explained how the DOST's portable digester converts agricultural wastes to biogas and shared that the digester is also adopted in other parts of the Philippines.

Engr. Herrera explained how the DOST's portable digester converts agricultural wastes to biogas and shared that the digester is also adopted in other parts of the Philippines.

The ESC staff demonstrated the biodigestion process to the delegates, from feeding the one-cubic meter digester with manure and their "secret" ingredients of fish gut and gills emulsion. The mixture takes, at most, 30 days to mature initially. With its successful pilot demonstration, the municipality plans to expand operations using pig manure from their forthcoming slaughterhouse.

ESC staff demonstrated how they mix the scraps collected from the public market and households in Tunasan. Digestate samples are collected from the digesters to aid in the composting process.

ESC staff demonstrated how they mix the scraps collected from the public market and households in Tunasan. Digestate samples are collected from the digesters to aid in the composting process.

During the demonstrations, Engr. Alon and Engr. Herrera stressed that biogas requires a specialized stove with a low-pressure nozzle larger than the standard LPG. It also cannot be used for direct heating, such as barbecue cooking.

The delegates also toured the facility, including its urban mini farm with ostriches and pigs and sorting area for reject fruit and vegetables collected from the markets and households within the municipality.

The training ended with insights from the participants, emphasizing how the younger generations can participate in initiatives for climate change mitigation. The delegates also expressed interest in adopting the technology, while Dr. Luis, Engr. Alon and Engr. Herrera said they continuously support the project and are committed to potential group collaborations. A participant from Laguna LGU states that the training is essential for reducing global warming and recognizes that this type of training is necessary for farmers. But it would only be worthwhile if several farmers still practiced rice straw burning. LGUs must strengthen their implementation of prohibiting GHG emission activities, stating, "Nagsisimula sa LGU ang pagbabago."

John Marion De Gracia, a participant from the Science City of Muñoz, Nueva Ecija expressed willingness to adopt the technology so that, "Pwede kaming maging model para sa ibang bayan," he added.

In his closing remark, Dr. Luis stressed the public's role as stewards of the environment. "We must take care of our present for the next generation," he said.

Trained biogas participants learned about the circular connection of waste segregation, anaerobic digestion, composting, and greening programs at Muntinlupa City. The yellow composter has served the city for over 16 years.

Trained biogas participants learned about the circular connection of waste segregation, anaerobic digestion, composting, and greening programs at Muntinlupa City. The yellow composter has served the city for over 16 years.

From small step to big sweep

Most of the participants expressed a desire to adopt the biodigester. For them, technology would prevent poor rice straw handling and reduce greenhouse gas emissions. Also, they emphasized the importance of influencing mindsets through farmer-level training.

With this, the RSBH team offered to assist anyone who wishes to build a biodigester by connecting them to DOST.

The Rice Straw Biogas Hub project addresses environmental issues while building a community of informed and empowered people committed to making a difference. With this project, we are to enjoy low-carbon emission, guilt-free rice.

For additional information regarding the project, please contact